My OPPO BDP-105 has undergone several major transformations since its original purchase. What started out as a fine sounding streaming player right out of the box has been upgraded to a true high-end streaming media device through careful attention to proper modifications. Many articles appear on the web regarding tweaks, upgrades, and hints on "how to DIY" fixes for such a stellar product and this blog is no different.

After reading about what others have tried, I used what they suggested in combination with what I already knew "worked " and came up with a series of modifications that made my ears rejoice. It takes a while as you push your system to musical nirvana but with each change you climb one more rung up the long, long ladder.

The latest discovery is a paper-in-oil capacitor, nothing new to the universe but new to me. Finding the right combination of equipment, cables, line filtering, and capacitors to resemble reality is what this hobby is all about but when it all comes together, you get that magic that transforms your listening pleasure from something that sounds great into something that sounds real. You hear the details the reviewers write about coming from your own speakers and you understand that they are anything but crazy. Even lowly MP3s sound decent but when compared to a SOTA DSD, you understand why some accomplished musicians are seeking higher and higher resolution for their recordings. It's that obvious.

I recently considered removing the DC-blocking capacitors from the final analog output stage of my BDP-105 but after further consideration I decided against it. If I ever took my OPPO to someone's home, it would have to accommodate a possible DC offset from the OPPO (read DC blocking capacitor input of their preamp). So I went off to work figuring out how to safely shunt the stock capacitors. To start, one must be certain which capacitors one needs to shunt. Below is the audio schematic for the BDP-105 (note CE93 and CE94 are the 100uF/16V DC-blocking capacitors).

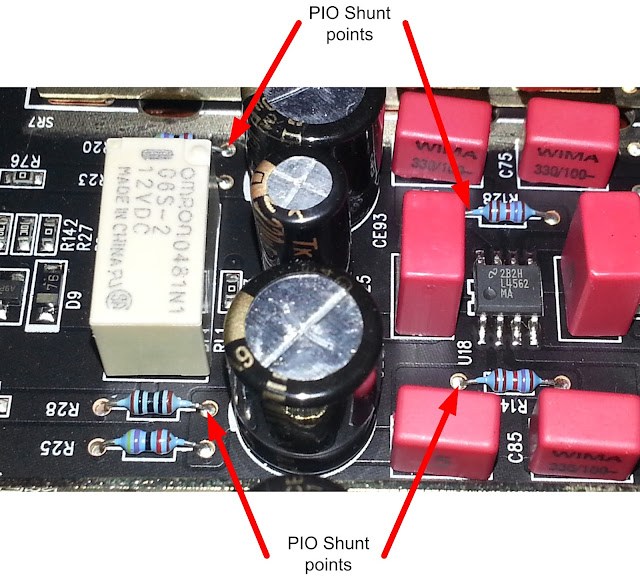

Others have used shunt capacitors from the underside of the PC board but the PIO capacitors I chose are quite large (about 3/4" in diameter) and will not fit. The task was to figure out where to add wires to the ends of the readily-accessible resistor leads to accomplish the same results as soldering them to the underside. Note from the above schematic that R128/R140 connect to one end of this capacitor. Resistors R23/R28 (or R25/R20) connect to the other end. Below is a highly magnified view of the output stage showing where these resistors are located from the top of the PC board. The red arrows show which resistor ends are used and the rear of the chassis is on the left.

The Mod

The first thing I did was to insulate the metal body of the PIO capacitor by putting heat-shrink tubing around it (for obvious reasons). Fortunately I had some

large tubing left over from a tonearm modification I performed a while back and after a few

minutes these capacitor grew in diameter to just over 3/4".

The next step is to remove and replace the stock ferrous-alloy leads of the capacitor. These leads are soldered to the end terminal of the capacitor; heating the wire and removing it is not recommended since it may damage the capacitor. But cutting the wire short off at the terminal eliminates the two inches of ferrous alloy and provides a point where the new wires can be attached. I chose to use new wires made from two twisted strands of #26AWG Teflon-insulated silver-plated OFHC wire-wrap wire.

Now comes the tricky part: connecting these new wires to the resistor leads. In concept, this should be a "no-brainer" to the average DIY tweaker but the component density on the OPPO is quite high making it necessary to use a fine-point tip and very low heat on the soldering iron. In reality, soldering the wire-wrap wires to these resistors takes a lot of patience to get a good solder joint without destroying surrounding components, lifting the trace off of the PC board, or disrupting the integrity of other existing connections. In other words, this mod is not for the inexperienced or faint of heart. Feeding the wires under the resistor lead provides the best electrical+mechanical connection but I found this to be impossible without lifting the resistor out of place. So the next best solution is to make a non-mechanical connection (just tack the wire to the side of the resistor lead). This "works" but it is not a truly professional solution. If I had used just one #26AWG wire, I could have fed that wire under the resistor lead (hind sight is always 20/20).

Finally, I attached the free-floating capacitor to some surrounding electrolytics with a few dabs of hot glue and the mod is done.

The Sound

Frankly, this is initially a subtle mod that requires some patience to appreciate. What to listen for is the fullness of the strings in a guitar body and the inner detailing of its harmonics. A good piece to use as a before/after test is Nils Lofgren's "Kieth Don't Go" on his 2006

Acoustic Live album. Although only a 16/44 recording, it clearly provides evidence to the fruits of your efforts. Listen to the timbre and color of the lower strings as Nils artistically plucks them. Listen to the inner detail of the guitar body in response to how hard the string is plucked and where/when he rests his palm on the body to contour/alter its sound. This is the region I noticed most of the changes to occur.

My wife, a movie fan, even commented on how dramatic and forceful the sound now emanates from the system. Historically, asking her if she notices a change in the sound after a modification yields a simple response "It sounds great!" which loosely translated means she likes it but cannot articulate why. This time she was able to fit words into her perception and the results is another successful modification.

The capacitors took a mere 10 hours to break in and the sound is now so sweet and mellow that one may easily compare it to that of a good tube. You will notice a definite change, one that is very easy to get used to. Instruments that may once have been "strained" are now more accurately reproduced fully. Saxophones have that unique round "bell" sound that one hears in a live performance but rarely finds in a home stereo system. Sounds once blurred appear cleaner and vocals, well just listen and you will not be disappointed.

See also

http://audiophile-musings.blogspot.com/2014/09/an-easy-oppo-bdp-105-modification.html

for another great idea on upgrading your OPPO.

Yours for higher fidelity,

Philip Rastocny

I do not use ads in this blog to help support my efforts. If you like what you are reading,

please remember to reciprocate by purchasing one of my eBooks or through a PayPal donation, My newest title is called

Where, oh Where did the Star of Bethlehem Go? It’s

an astronomer’s look at what this celestial object may have been, who

the "Wise Men" were, and where they came from. Written in an

investigative journalism style (like that of the Discovery Channel), it

targets one star that has never been considered before and builds a

solid case for its candidacy.

My other titles include:

Copyright

© 2015 by Philip Rastocny. All rights reserved.